Polycondensation Plants

Contact Persons

This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel. +49 - 221 - 37 92-0

Fax +49 - 221 - 37 92-299

Polycondensation Plants

Alkyd Resins

Alkyd resins are manufactured by the condensation of dicarboxylic acids (mostly in the form of their anhydrides) with polyols and monocarboxylic acids at temperatures between 200 and 270°C. The monocarboxylic acids may either be generated “in situ” in a first reaction step by alcoholysis of vegetable oils („two-step-process“) or added in their pure form („fatty-acid-process“).

JM/RHE designed alkyd resin plants include the following characteristics

- an effective agitator, developed by JM/RHE, with a variable frequency drive through which the shaft speed can be adjusted to all requirements;

- reduced heating and cooling times through the integration of external and internal reactor coils into the thermal oil secondary circuit;

- the fully automatic manufacture of alkyd resins to analytical target values with a unique viscosity and acid number testing circuit.

Saturated and Unsaturated Polyester Resins

Polyester resins are manufactured by the condensation of dicarboxylic acid derivatives such as phthalic acid anhydride and maleic acid anhydride and adipic acid (production of saturated polyesters) or anhydrides and fumaric acid (production of unsaturated polyesters) with polyols at temperatures between 200 and 240°C.

JM/RHE designed polyester resin plants include the following characteristics

- an effective agitator, developed by JM/RHE, with a variable frequency drive through which the shaft speed can be adjusted to all requirements;

- reduced heating and cooling times through the integration of external and internal reactor coils into the thermal oil secondary circuit;

- the special design of the distillation overheads for the minimization of glycol losses and improvement of the product quality;

- the fully automatic manufacture of polyester resins to analytical target values with a unique viscosity and acid number testing circuit.

Phenolic Resins

Phenolic resins ar manufactured by an acid or caustic initiated condensation reaction of (substituted) phenols with aldehydes, predominantly formaldehyde, at temperatures between 50 and 120°C.

1. Novolaks

Novolaks are produced by condensation in acidic medium with a molar excess of phenol. After the completion of the highly exothermic reaction, the water is distilled off under vacuum and the fused resin is passed onto a cooling belt for solidification.

Amongst others Novolaks are used as binder for moulding compounds.

2. Resols

Resols are produced by condensation in caustic medium with a molar excess of formaldehyde. Low condensed resins are cooled and filtered. Higher condensed resols are washed free of caustic, the water is separated, if necessary by distillation under vacuum and the product is filtered.

JM/RHE designed phenolic resin plants include the following characteristics:

- an effective agitator, developed by JM/RHE, with a variable frequency drive through which the shaft speed can be adjusted to all requirements;

- reduced heating and cooling times through the integration of external and internal reactor coils into the heating and cooling circuit;

- the automatic adjustment of the pH value of the reaction mix through an online pH meter

- the fully automatic manufacture of phenolic resins to analytical target values with a unique viscosity testing circuit.

Urea Resins

Water borne urea resin solutions are manufactured by a condensation process from urea and formaldehyde after the addition of acids and caustic solutions at temperatures between 60 and 90°C. The formaldehyde can be introduced either as 37 – 55% aqueous solution or as urea formaldehyde precondensate (UFC).

Solid urea resins are amongst others used as binder for moulding compounds.

JM/RHE designed urea resin plants include the following characteristics

- an effective agitator, developed by JM/RHE, with a variable frequency drive through which the shaft speed can be adjusted to all requirements;

- reduced heating and cooling times through the integration of external and internal reactor coils into the heating and cooling circuit;

- the automatic adjustment of the pH value of the reaction mix through an online pH meter;

- an inhibitor unit to prevent an uncontrollable condensation reaction in the reactor;

- the cooling of UF, UMF and MUF glue resins through heat exchangers during the product transfer from the reactor to the storage tank.

For the manufacture of glue and impregnation resins employed in the wood processing industry, JM/RHE disposes of its own technological know-how, so that production plants and recipes can be offered as a package.

Melamine Resins

Melamine resins are manufactured by a condensation process from melamine and formaldehyde after the addition of acids and caustic solutions at temperatures between 60 and 90°C.

Solid melamine resins are amongst others used as binder for moulding compounds.

JM/RHE designed melamine resin plants include the following characteristics

- an effective agitator, developed by JM/RHE, with a variable frequency drive through which the shaft speed can be adjusted to all requirements;

- reduced heating and cooling times through the integration of external and internal reactor coils into the heating and cooling circuit;

- the automatic adjustment of the pH value of the reaction mix through an online pH meter;

For the manufacture of impregnation resins employed in the wood processing industry, JM/RHE disposes of its own technological know-how, so that production plants and recipes can be offered as a package.

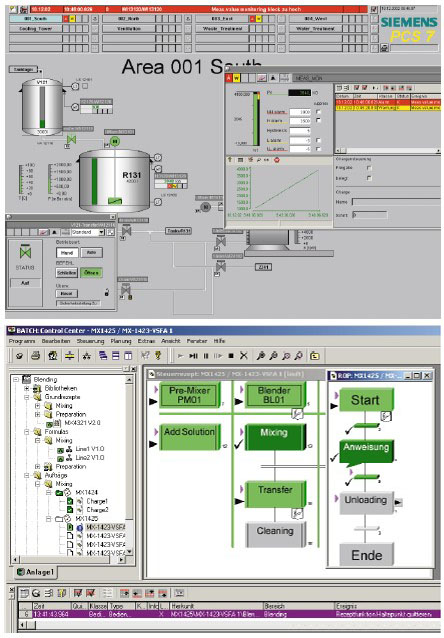

Process Control System

The plants for the production of synthetic resins and polymer emulsions offered by the RHE product group preferably come with a SIEMENS SIMATIC PCS7 process control system. This well-proven process control system is designed to meet the highest standards of performance and reliability in chemical plant automation.

Designed as a uniform and homogeneous complete system, SIMATIC PCS 7 meets the special demands on a process control system especially with regard to batch-oriented operation:

- simple and reliable process control for reproducible product qualities

- user-friendly operation and visualization thanks to an operating concept including the plant view

- flexible solutions for batch processes

Its modular structure enables the process control system to be adapted and subsequently expanded or reconfigured, e. g. in order to correspond to new conditions in case of increases in capacity or technological modifications.

The operator surface has a clear and ergonomic design, so the operator can monitor the process through displays of the plant components and can change quickly between different plant views.

The automation of batch processing is effected via the SIMATIC BATCH module, the main components of which are a Batch Control Center (BatchCC) and a recipe editor.

BatchCC enables comfortable order and batch planning and offers powerful functions for monitoring, controlling and recording of batch processing.

For instance, the operator can select a saved recipe which is then executed almost fully automatically.

The recipe editor is a comfortable tool for creating, modifying, and documenting master recipes.

All in all, SIEMENS SIMATIC PCS7 together with SIMATIC BATCH CC is a powerful and user-friendly process control system ensuring smooth plant operation.

DE

DE  EN

EN