Polymerization Plants

Contact Persons

Tel. +49 - 221 - 37 92-0

Fax +49 - 221 - 37 92-299

Polymerization Plants

Acrylic Resins

Acrylic resins are manufactured by catalyst initiated radical polymerization of acrylic and methacrylic acid derivatives such as esters, amides and nitriles in an organic solvent at temperatures between 80 and 150°C.

JM/RHE designed acrylic resin plants include the following characteristics

- an effective agitator, developed by JM/RHE, with a variable frequency drive through which the shaft speed can be adjusted to all requirements and which exerts low shearing forces through its special design;

- reduced heating and cooling times through the integration of external and internal reactor coils into the heating and cooling circuit;

- the inhibitor unit for an emergency break-off of premature polymerization reactions in the monomer blending tank.

Acrylic Emulsions und Polyvinylacetate Emulsions

Polymer emulsions are manufactured by a catalyst initiated radical polymerization process from unsaturated monomers in an aqueous medium at temperatures between 60 and 90°C. The main monomers are acrylic and methacrylic acid derivatives, vinyl acetate and styrene; water soluble peroxides are the most important initiators for the polymerization reaction. For the stabilization of the polymer particles emulsifiers and protective colloids dissolved in water are employed.

JM/RHE designed polymer emulsion plants include the following characteristics

- an effective agitator, developed by JM/RHE, with a variable frequency drive through which the shaft speed can be adjusted to all requirements and which exerts low shearing forces through its special design;

- the enthalpy measurement system in the heating and cooling circuit for a precise indication of the reaction start and the continuous monitoring of the reaction progress;

- the cooling of the reactor head through thermoplates or half-pipe coils for facilitating reactor cleaning operations;

- the inhibitor unit for an emergency break-off of premature polymerization reactions in the monomer blending tank.

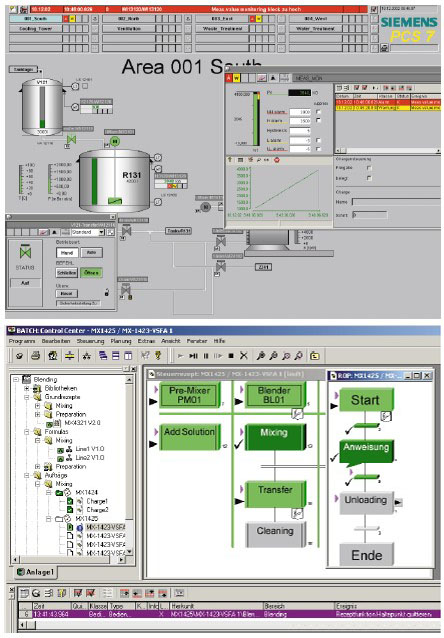

Process Control System

The plants for the production of synthetic resins and polymer emulsions offered by the RHE product group preferably come with a SIEMENS SIMATIC PCS7 process control system. This well-proven process control system is designed to meet the highest standards of performance and reliability in chemical plant automation.

Designed as a uniform and homogeneous complete system, SIMATIC PCS 7 meets the special demands on a process control system especially with regard to batch-oriented operation:

- simple and reliable process control for reproducible product qualities

- user-friendly operation and visualization thanks to an operating concept including the plant view

- flexible solutions for batch processes

Its modular structure enables the process control system to be adapted and subsequently expanded or reconfigured, e. g. in order to correspond to new conditions in case of increases in capacity or technological modifications.

The operator surface has a clear and ergonomic design, so the operator can monitor the process through displays of the plant components and can change quickly between different plant views.

The automation of batch processing is effected via the SIMATIC BATCH module, the main components of which are a Batch Control Center (BatchCC) and a recipe editor.

BatchCC enables comfortable order and batch planning and offers powerful functions for monitoring, controlling and recording of batch processing.

For instance, the operator can select a saved recipe which is then executed almost fully automatically.

The recipe editor is a comfortable tool for creating, modifying, and documenting master recipes.

All in all, SIEMENS SIMATIC PCS7 together with SIMATIC BATCH CC is a powerful and user-friendly process control system ensuring smooth plant operation.

DE

DE  EN

EN